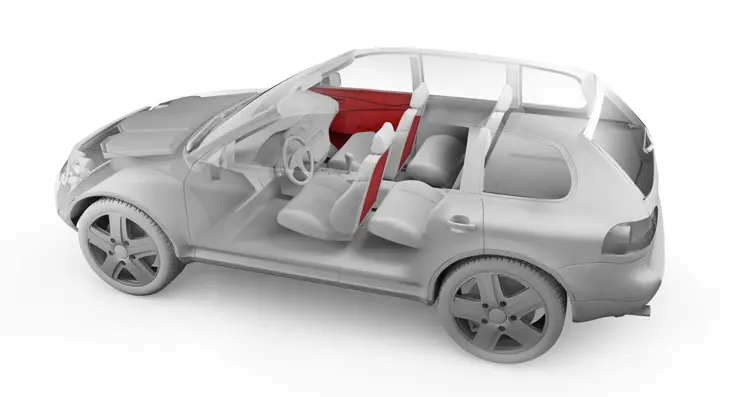

Door panels and seatbacks

Materials processed:

NFPP, HFFS, leather, fake leather, PU, PVC, TPO

Processes:

Forming, glueless covering, vacuum covering, press covering; one-step forming and covering; one-step forming, covering and punching; one-step forming with back injection; press covering and edge folding; edge folding, press covering and punching; in-mold grain laminating (IMGL), EcoCover®, foaming, in-groove covering, punching, assembling

Technologies:

Pinch trimming, bypass punching, painting, spraying, thermal oil conditioning, water conditioning, electrical heating, infrared (IR) heating, hot air heating, ultrasonic (US) welding, gluing, infrared (IR) welding

NFPP, HFFS, leather, fake leather, PU, PVC, TPO

Processes:

Forming, glueless covering, vacuum covering, press covering; one-step forming and covering; one-step forming, covering and punching; one-step forming with back injection; press covering and edge folding; edge folding, press covering and punching; in-mold grain laminating (IMGL), EcoCover®, foaming, in-groove covering, punching, assembling

Technologies:

Pinch trimming, bypass punching, painting, spraying, thermal oil conditioning, water conditioning, electrical heating, infrared (IR) heating, hot air heating, ultrasonic (US) welding, gluing, infrared (IR) welding

Production process