Edge Folding Lines

Your solution to produce the ultimate finish!

Looking for a high-quality appearance?

During the edge folding process, extra covering material is glued and wrapped around the part edges.

Persico offers 2 different edge folding systems:

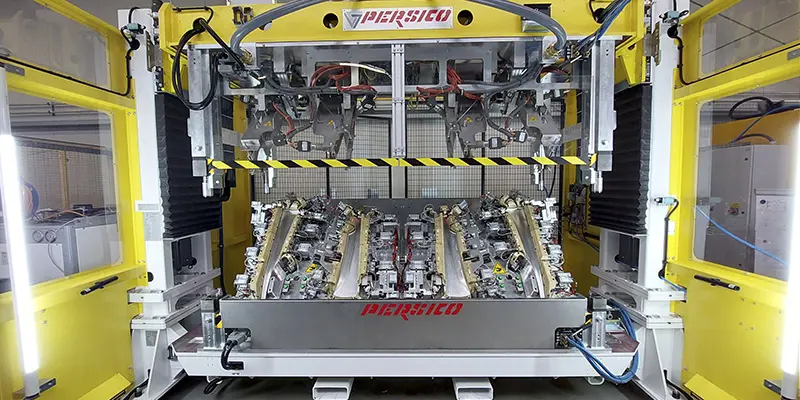

- PESS (PERSICO EDGE FOLDING SINGLE STATION) Single station machine

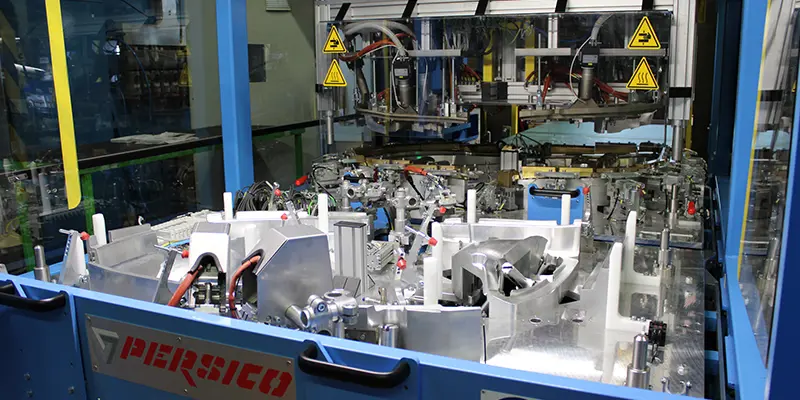

- PEIS (PERSICO EDGE FOLDING INLINE STATION) Inline machine

The right choice is based on your needs.

Edge folding can be performed with or without gluing, depending on the starting materials.

Single station machine advantages

- Easy to use

- Vertical movement

- Small footprint

- Tool change system

- Possible tilting to improve ergonomics

- Possible independent tool commissioning

- Different possible edge folding technologies

- Easy to relocate

Fields of application

- Door carriers, top rolls, inserts, map pockets, armrests

- Centre consoles

- Instrument panels

- Seat back panels

- Headliners

- Pillars

- Parcel shelves

- Load floors

Optional features

- Automatic part handling (loading and unloading)

- Hot “kiss cut”

- Semi-automatic tool changing

- Others upon request

Inline machine advantages

- Short cycle times

- Realization of edge folding in complicated areas through division into several stations

- Potential combination with other technologies (joining, welding, punching)

- Possible part handling by robots

- Possible detensioning cuts for better edge folding quality

- Easy to relocate

Fields of application

- Door carriers, top rolls, inserts, map pockets, armrests

- Centre consoles

- Instrument panels

- Seatback panels

- Pillars

Optional features

- Automatic part handling (loading and unloading)

- Hot “kiss cut”

- Semi-automatic tool changing

- Others upon request